AGV Controller

This project was part of my second job and was a massive, systematic effort. It took over three years to develop the controller hardware, firmware, wiring harness, tuning tool software, and tuning SOPs.

I spent most of my time designing the controller firmware and conducting tests.

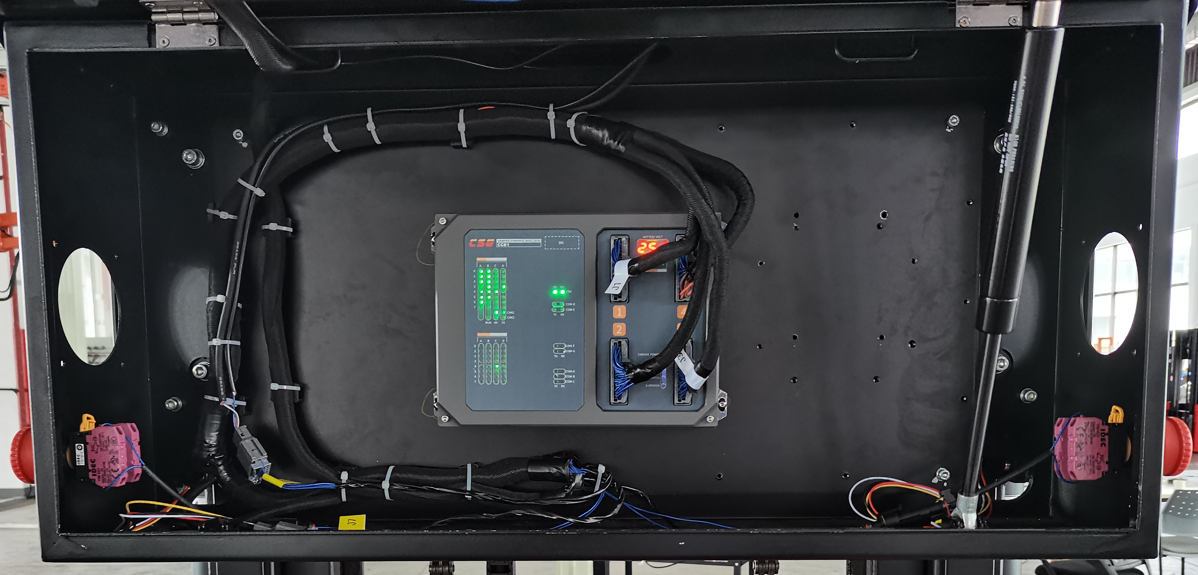

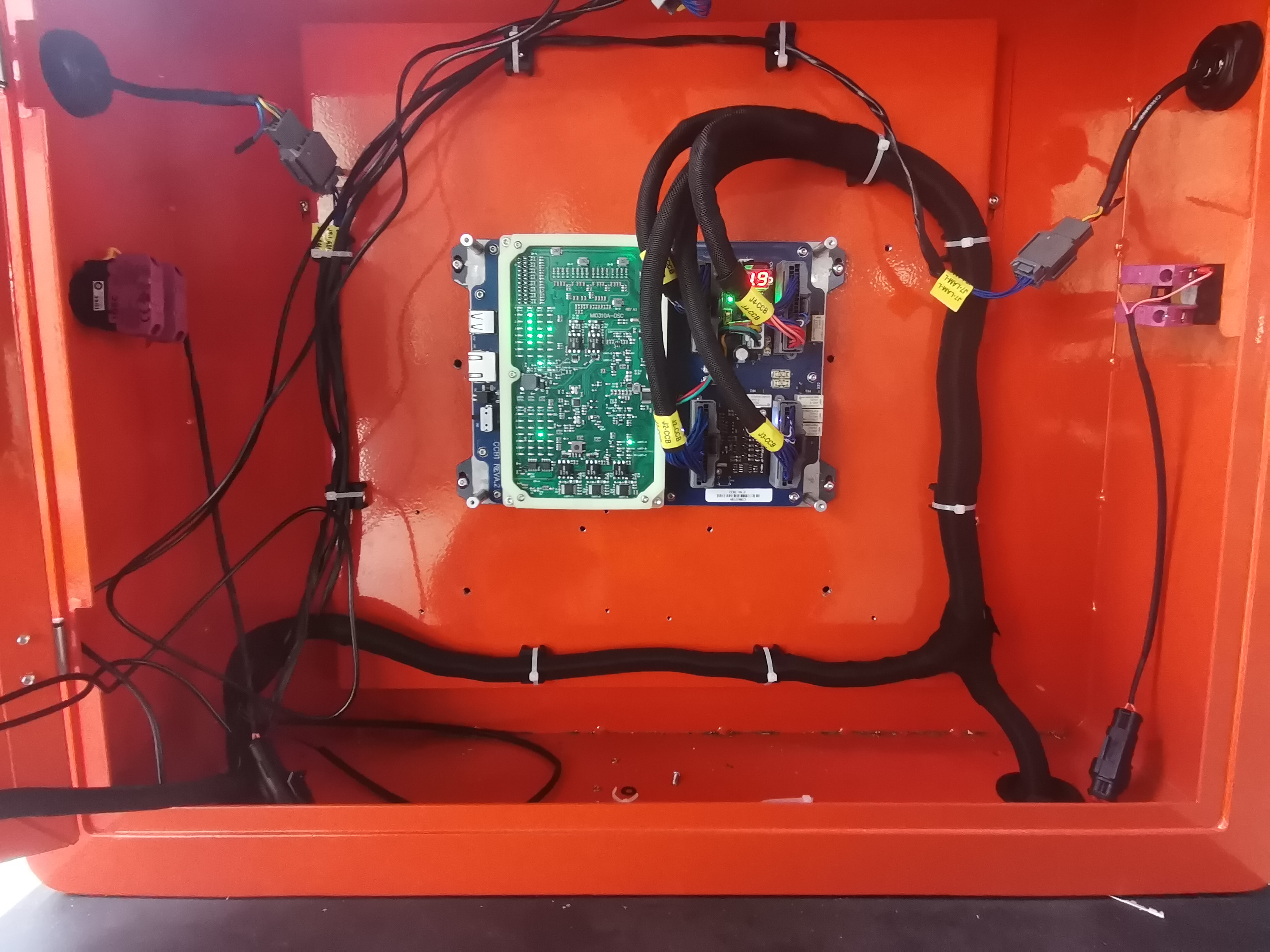

1. The Controller

| The controller without a case | Inside the controller | The Controller has a 7" HMI |

|---|---|---|

|  |  |

This is the third version of the controller—I iterated three times to refine it into an all-in-one central control box. Its design was inspired by a car's DCS (Distributed Control System).

The controller also includes a standalone control panel, which features a 7" touchscreen, Wi-Fi module, loudspeaker, buttons, and a remote control socket.

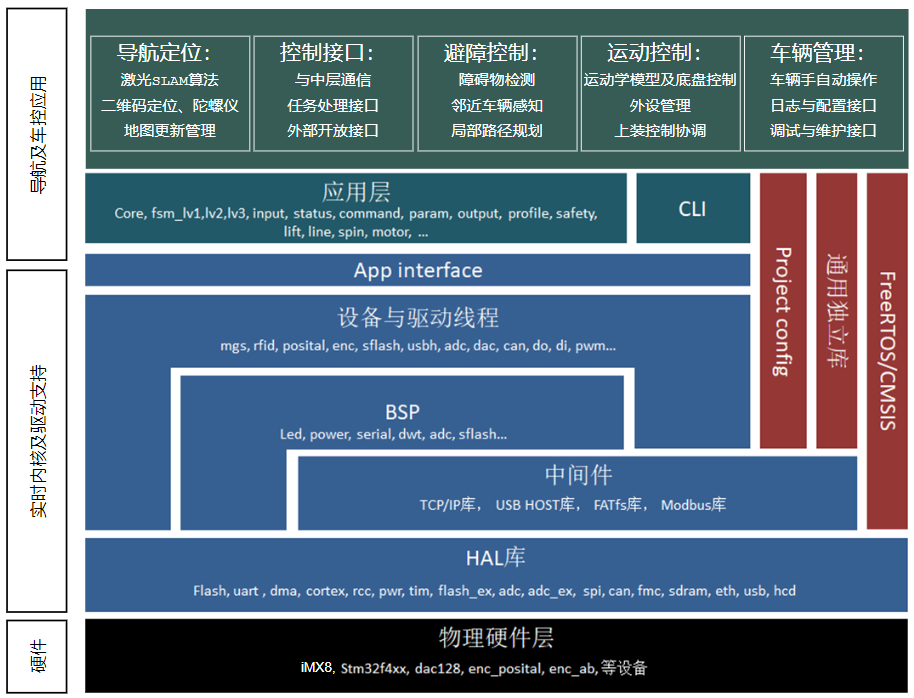

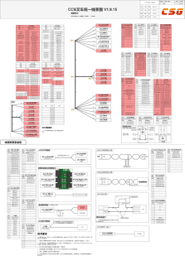

2. Unified Firmware Design

The controller software/firmware was designed to provide configurable settings to accommodate different chassis.

| Architecture | Application1 | Application2 | Application3 |

|---|---|---|---|

|  |  |  |

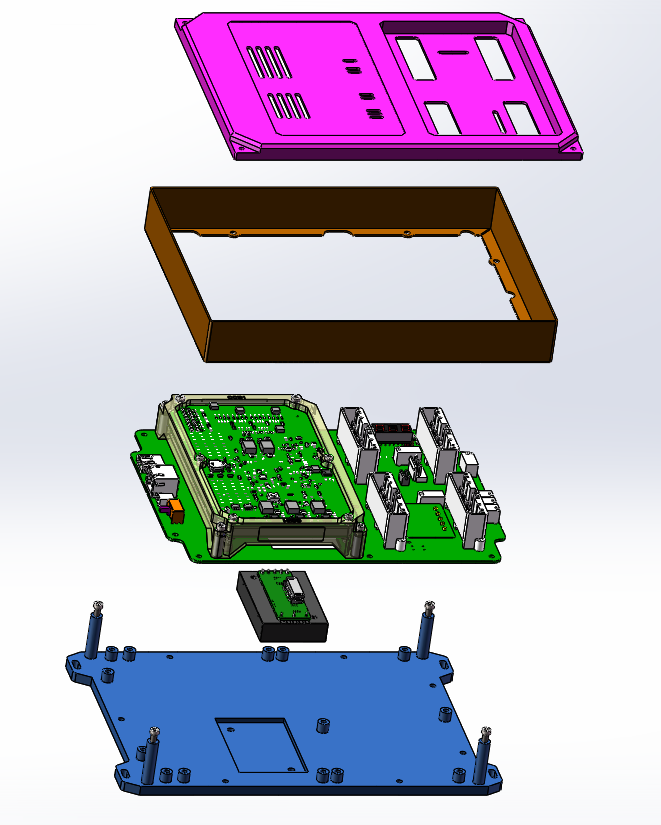

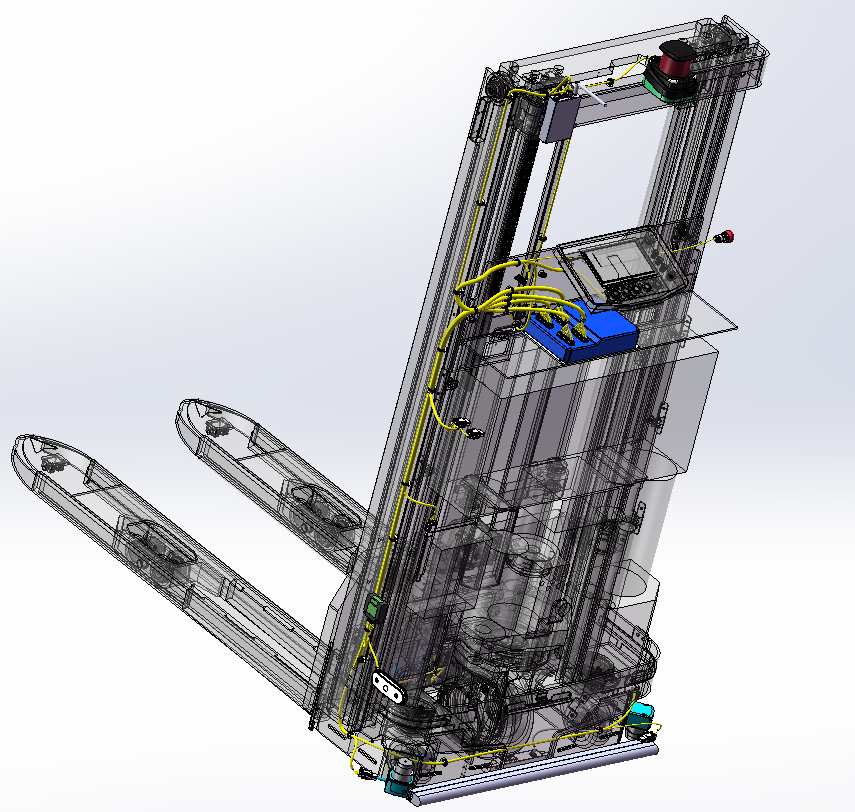

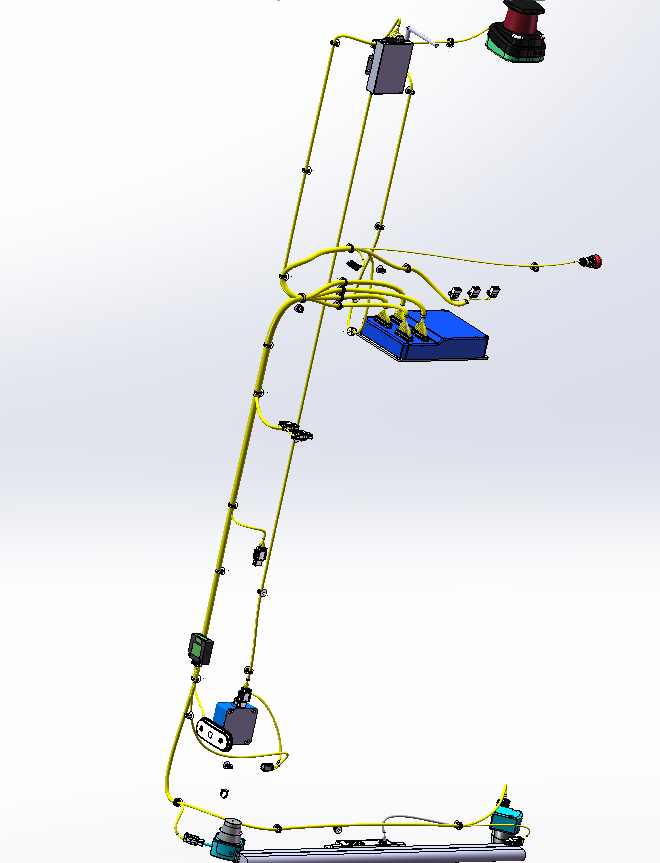

3. Unified Harness Design

I also spent a little time learning SolidWorks Harness and then designed a unified harness for the controller. The length of each branch was adjustable to fit different applications.

| Harness | Virtual simulation | |

|---|---|---|

|  |  |

|  |  |

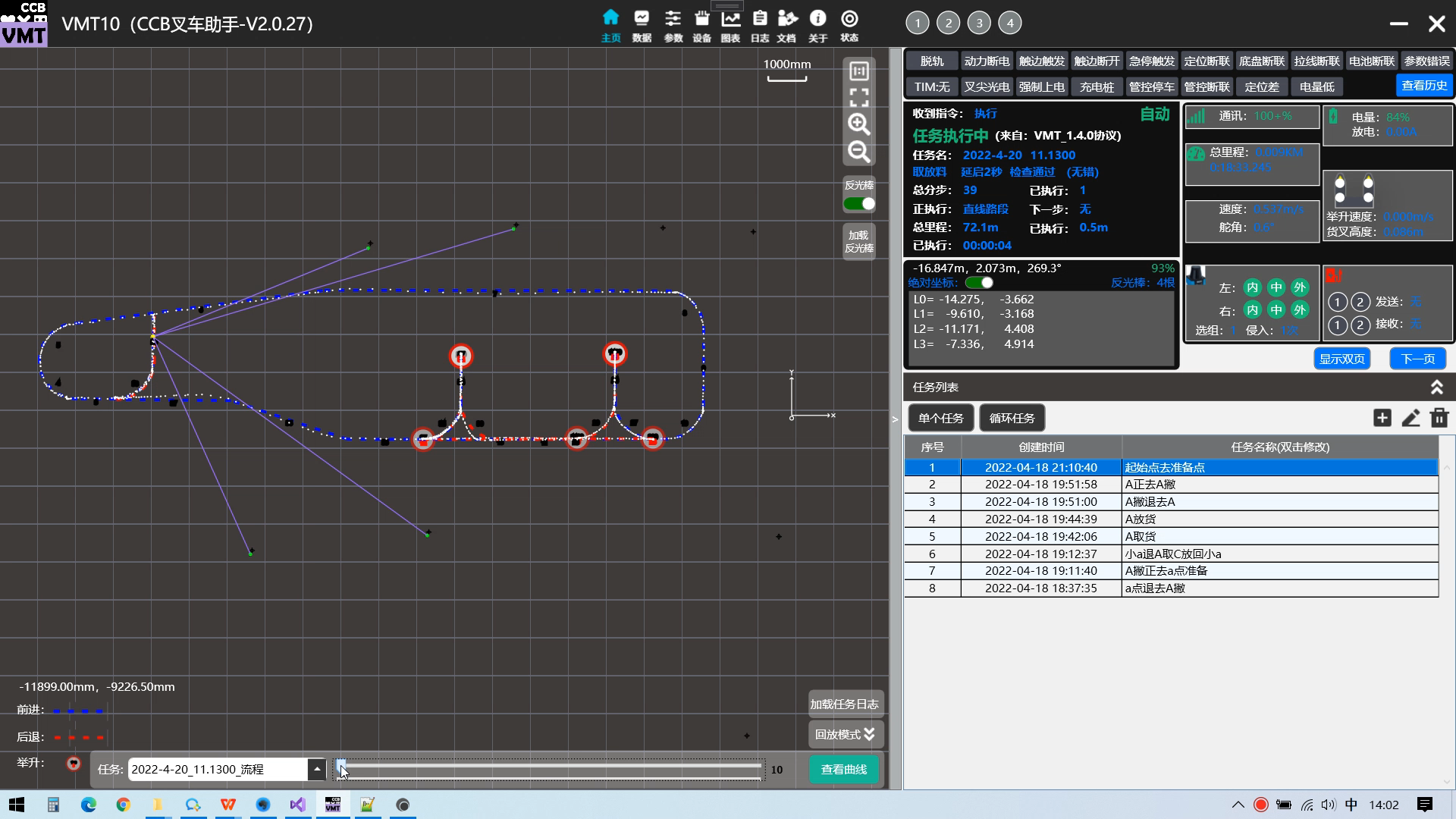

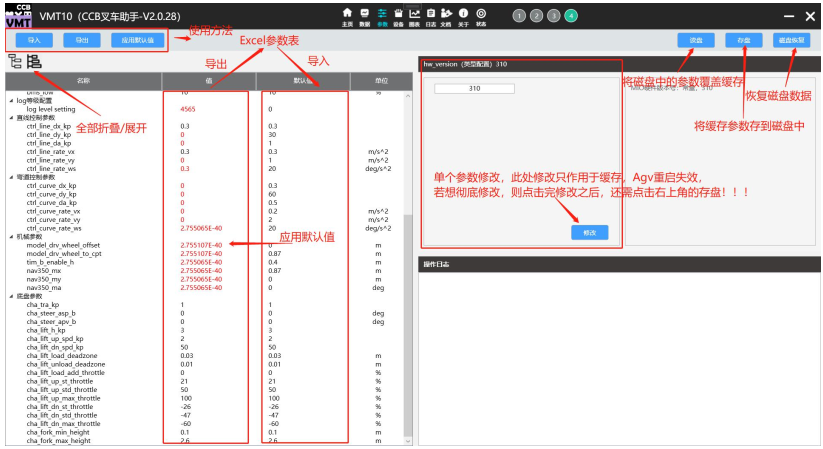

4. Vehicle Maintenance Tool

Viewing a vehicle in operation

Creating tasks for vehicles

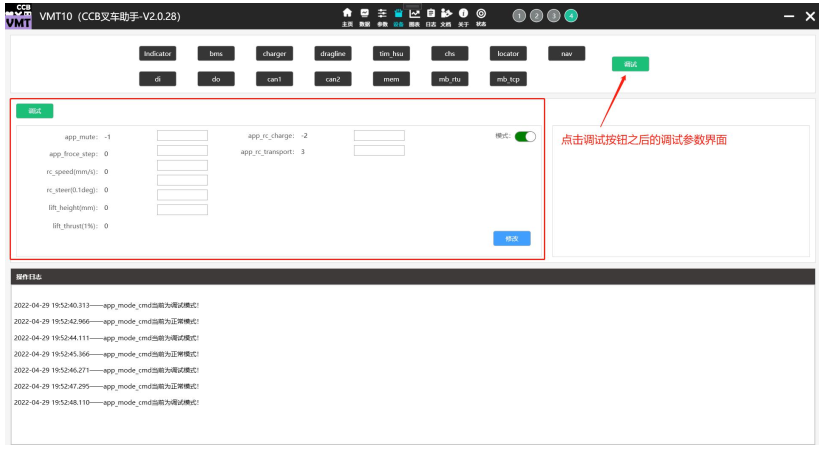

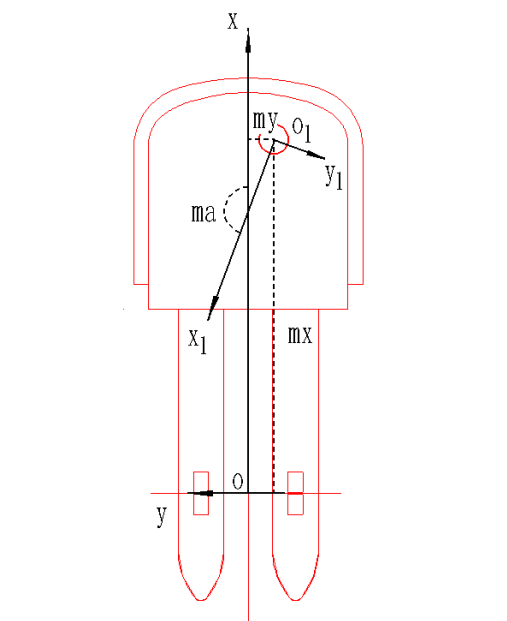

5. FAE/AE system

It was about lots of SOPs and experiments.

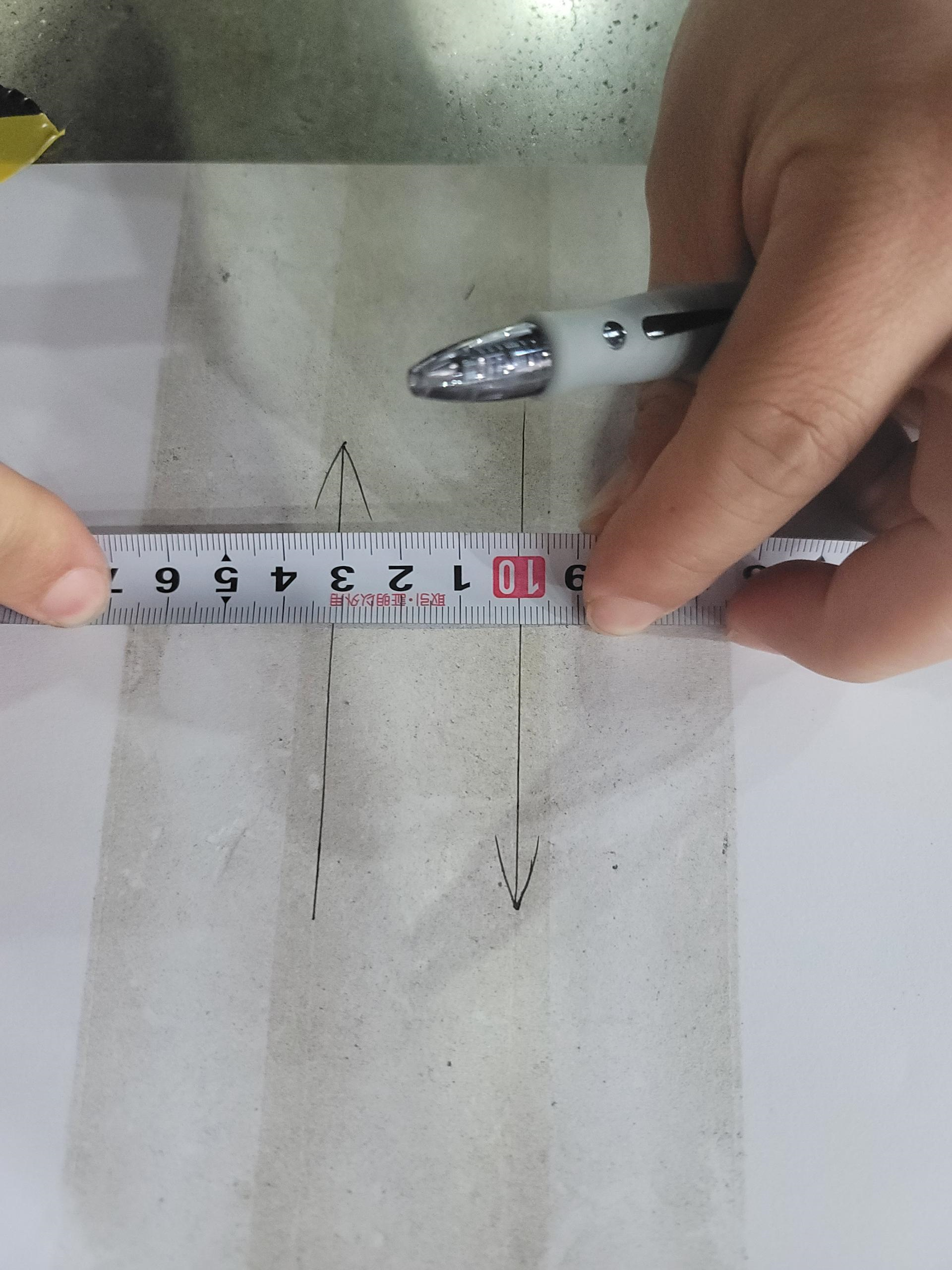

| Chassis | Measurement | Caliberation | Tunning |

|---|---|---|---|

|  |  |  |

6. Applications

| 1 | 2 | 3 | 4 |

|---|---|---|---|

|  |  |  |

Repetition precision test

(I have permission to use the images in this blog.)